Table of Contents

A Surge Analysis: What Is It?

Surge Analysis Of Industrial Piping System Across U.S. The concept of surge analysis is meant only for the analysis of pressure oscillations in a piping system which arises due to operational changes like opening or closing of the valve, or start up or shut down of pumps, etc. If these pressure variations either from planned events or unanticipated disruptions are not managed properly, they can be extremely stressful

on the system. It is important to analyse this behaviour as it allows potential problems relating to these quick changes in pressure to be identified. Surge analysis is employed in industries throughout the U.S., from the petrochemical hubs of Houston, Texas, to the automotive manufacturing plants of Detroit, Michigan, to the aerospace facilities of Phoenix, Arizona, etc. to provide safe and efficient operations.

Why is surge analysis necessary?

Surge Analysis Is Critical for Fluid Transport Systems Across the U.S. Pipeline systems, which are the most economical and safer means of transporting both liquids and gases, need to be designed and operated with the aid of surge analysis, as shall be seen. Inevitably, these systems which contain valves, elbows, reducers and traverse across entire terrain having curves and elevation changes are susceptible to sudden pressure surge.

Many fluid surges are the result of emergencies or routine operational events that interrupt the steady flow of fluid with sudden changes in momentum and high surges in pressure. Such pressure changes can be highly destructive to facilities and personnel, as well as to pipelines.

Surge analysis is critical—both in Houston, Texas, where gigantic oil refineries and chemical processing plants exist, and in Baton Rouge, Louisiana; Los Angeles, California; and across Pennsylvania and Ohio natural gas infrastructure. This prevents the structural failure of pipeline systems, minimizes the risk of disastrous failure, and aids in safe and efficient operations throughout American industrial diversity.

When should one perform a surge analysis in U.S. Pipeline Systems?

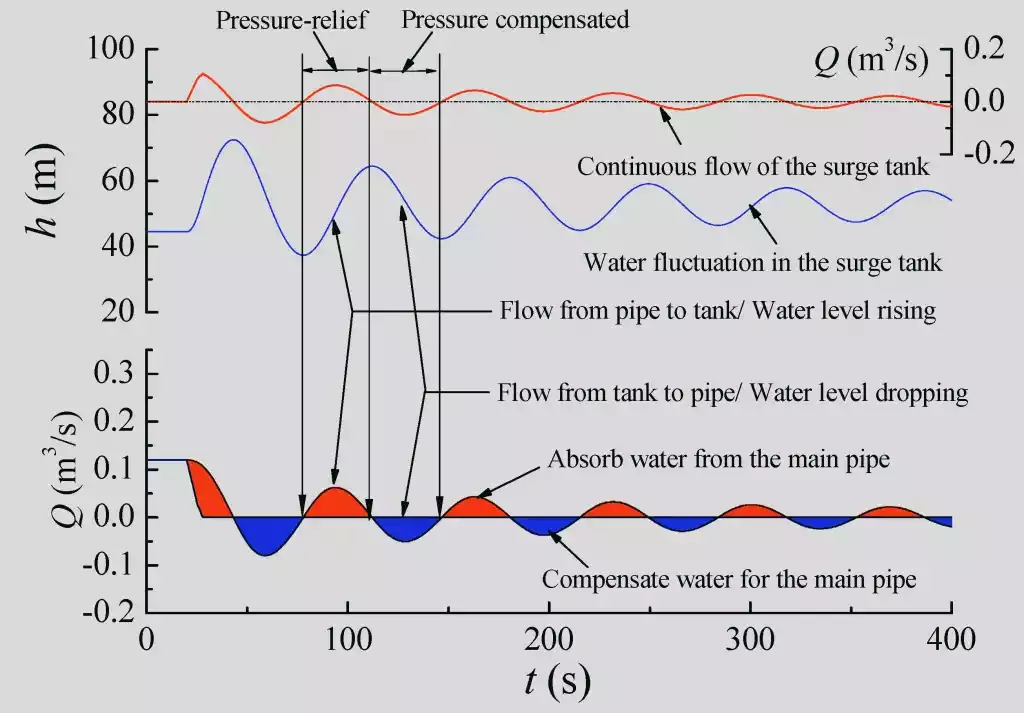

Surge analysis has traditionally been performed in today’s industrial pipelines whenever the pipeline system moves from a designed steady state condition to a transient, unstable state because of changes in operation condition. In this case, these shifts can occur due to irregular events which cause disturbance to flow and pressure rates, for example: rapid opening or closing of valves, startup or shutdown of pumps or any other modes of changes

in operations. The surge is executed until the system does not restabilize to a new steady state condition. It is particularly important during the design phase for new installations, major upgrade or expansion, or change in operational protocols. Surge analysis is used to make sure that systems in refined petroleum networks in Corpus Christi, Texas, water infrastructure projects in Denver, Colorado, and natural gas systems in North Dakota’s Bakken region can operate safely under such conditions. It is a preventative step that can lessen damage, downtime, as well as safety and compliance for pipeline operations.

Piping surge: what is it?

A piping surge occurs when the velocity of fluid in a pipe suddenly changes, usually (but not always) initiated by the rapid starting or stopping of a pump, rapid opening or closing of a valve, or discharge of air in the system. These can cause drastic changes in pressure with potentially large increases or falls in pressure, thus stressing the pipeline and its constituents.

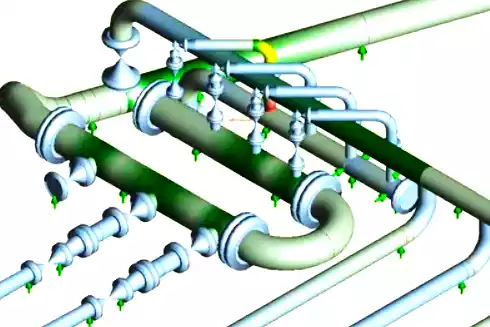

Surge analysis is a specialized hydraulic modeling process to determine the effects of these pressure fluctuations on the entire pipeline system. It addresses pipe, valve and fitting maximum allowable operating pressures, pressure control equipment and pump trip mechanism setting and placement, and sized and placement of surge reliefs, air releases, and remote or automatic controls.

Given this, it is important to make sure that a pipeline network, whether in natural gas transmission lines in Pennsylvania, crude oil pipelines in North Dakota or municipal water systems in Florida, can ‘handle’ these transient hydraulic events safely and efficiently. Integration of surge analysis into both the design and operational phases provides operators with the ability to reduce the risks, improve reliability and satisfy industry safety standards.

Alternate Names for Piping Surge Analysis in U.S. Engineering Practices

Different names exist for the piping surge analysis, but all of them concentrate the particular properties of the phenomena or the analytical procedure. This critical evaluation is known as a leak survey to oil and gas companies in Texas and municipal utilities in New York and is described by the following terms in all industries across the United States.

1. Hydraulic Transient Analysis: The word short term makes an implication on the short time period that he hydraulic conditions are dynamic in the pipeline systems. This work predominantly discusses how the fluid flow and pressure change with time, and exposes how systems react to unsteady state operations like pump starts up, and valve trim changes.

2. Water Hammer Analysis: This phrase is used to describe sudden pressure surges caused by rapid valve closures or pump shutdowns in most water containing liquid based systems. The curse of ‘hammer’ effect is particularly applicable in municipal water supply system or wastewater infrastructure projects in cities like Chicago, Seattle, etc.

3. Pressure Surge Analysis: In particular, this name emphasizes that the pressure spikes that would take place during operation due to e.g. pump trips or emergency shutdowns are today addressed. In Baton Rouge Louisiana, it is widely used in petrochemical facilities and in refinery pipelines all over California where it is essential to pressure limit while operating the system at high pressure for its integrity and safety.

By understanding what these terms are in regards to, engineers and operators can then select the right analysis methods to guarantee pipeline systems stay resilient when subjected to an array of transient conditions.

4. Transient Flow Analysis: Stresses temporary or changeable conditions of the flow in the system, not only pressure fluctuations but velocity and direction changes as well.

5. Pressure Transient Analysis: This is akin to hydraulic transients but differs in that regards pressure waves that are produced and propagated throughout the system when the system responds.

6. Fluid Transient Analysis: A term that can be used more generally for both liquid and gas systems in which the concern is with transient behavior of the fluid in the pipes.

7.Surge Pressure Analysis : It is the pressure change with respect to time or the pressure disturbances or pressure fluctuations. It mainly examines the maximum pressure that is experienced by the system in a given instance often during a transient event.

All these various names depict how according to the nature of the fluid within the piping systems, the causes of the transient events and the potential impacts that these have on the piping system, engineers may have different angles or areas of specialty to focus on while analyzing piping systems.

Analysis and Modeling of Surges:

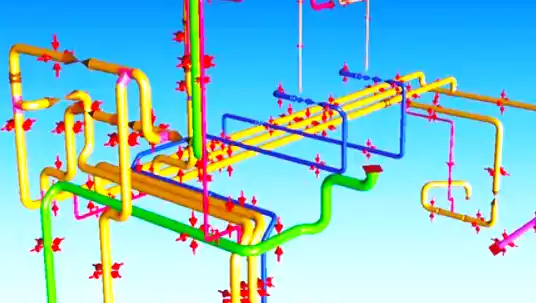

KKR Bose Design’s engineering team has detailed surge analysis experience for entire pipeline systems with critical components such as pumps, valves, reducers and control fittings. We start our process by collecting pipeline data from the client with such care that every detail of the system is represented in our models precisely as it is in reality.

Key inputs are needed to effectively perform a surge analysis.

- Pipeline geometry and layout (lengths, diameters, materials, elevations)

- Pump specifications (type, head, flow rate, start/stop behavior)

- Valve characteristics (types, opening/closing time, control method)

- Fluid properties (density, viscosity, compressibility)

- System operational data (steady-state flow rates and pressures)

- Control logic and automation parameters

- Locations of surge protection devices (such as relief valves, air chambers, and surge tanks)

Regardless whether it’s refined petroleum system in Texas, municipal water transmission system in California, or chemical transportation lines in Los Angeles, our surge analysis services keep your infrastructure protected against damaging pressure events to enable safe, reliable and regulation compliant operation.

Surge Analysis software available:

Although there are many programs on the market for doing surge analysis, the most popular ones are as follows:

- Pipeline Studio

- PIPENET

- Flowmaster

- Hytran

- AFT Impulse

- WANDA

- Hammer

- PASS/Hydro system

- Flownex Simulation Environment

- PTRAN

- KYPipe

When coming to the evaluation of the outcomes of the simulation, one should again observe the analyst’s technical decisions and the gathered experience to provide the best solutions. The implementation of strategies by the team in this organization is capable of offering the requisite back up and achieve the set goals. The key deliverables include:

– Basic engineering design

– Report of an analysis of surge with recommendation if any

– Technical assistance

– Control philosophy

Why Choose KKR Bose Design for Surge Analysis or Piping Flexibility Analysis?

- Deep Expertise: KKR Bose Design has a great deal of experience with pipe surge analysis, which guarantees that the company fully comprehends surge occurrences and how they affect piping systems.

- Advanced Analytical techniques: They accurately simulate and model surge events using cutting-edge software and techniques, enabling accurate analysis and trustworthy outcomes.

- Thorough Analysis: A wide range of surge analysis services, including in-depth simulations of transient situations and their consequences on system safety and performance, are provided by KKR Bose Design.

- Skilled Team: Their group of professionals possesses a plethora of technological know-how and is equipped to manage intricate surge analysis assignments and offer perceptive suggestions.

- Custom Solutions: They adjust their strategy to each project’s particular requirements, tackling particular difficulties and making sure that the answers are workable and efficient.

- Dedication to Quality: To guarantee the dependability and security of pipe systems, KKR Bose Design is committed to providing top-notch outcomes by following industry standards and finest practices.

- Customer-Centric Service: Throughout the analytical process, they provide clear communication and support, concentrating on comprehending and meeting the needs of the customer.

Selecting KKR Bose Design for piping surge analysis entails taking advantage of their knowledge, cutting-edge equipment, and dedication to producing thorough and superior study.