Table of Contents

Heat Exchanger Design Services in Singapore by KKR Bose Design :

At KKR Bose Design Singapore residents can obtain full-scale heat exchanger design services through our company. Our company provides cost-effective innovative efficient solutions for heat transfer needs at all locations throughout the districts of Jurong Tuas and Changi Business Park.

The expert engineers at KKR Bose Design manufacture heat exchangers which enhance system capabilities and reduce energy expenses and increase operational durability. All designs adhere to the highest international and regional standards for safety and reliability.

Our engineering team employs PV-ELITE software to build pressure vessels as well as API-compliant infrastructure along with computing long columns. Our deliverables include:

General Arrangement (GAD) Drawings

Nozzle Load Calculations

Support & Welding Details

Shell Development Drawings

The company generates Nameplate and Component Drawings which include content such as Ladder and Platform and Handrail.

The organization provides complete design documentation through calculations performed with Compress and E-Tank spreadsheets and custom-built spreadsheets.

The process industries in Singapore can trust KKR Bose Design to provide comprehensive heat exchanger solutions delivering accurate and exceptional results.

Why KKR Bose Design is the Best Choice for Heat Exchanger Design Services in Singapore:

Performance-Oriented Heat Exchanger Design Services Exist in Singapore

At KKR Bose Design we supply precise heat exchanger designs to Singapore-based commercial operations throughout Jurong Island and Tuas and its surrounding territories.

Heat Exchanger Design Services from our company need to be selected by customers because

✔ Tailored Engineering Solutions

Applications which require heat transfer need specialized solutions for every implementation. Our designs specifically fulfill operational requirements to generate maximum performance and efficiency rates.

✔ Advanced Technology for Accuracy

Our engineering software combined with simulation tools helps complete thermal and full mechanical evaluation of project designs to reach optimal solutions.

✔ High Performance at Reduced Costs

The company implements optimized specifications along with efficient systems paired with exact material selection to minimize operational expenses while delivering high performance quality.

✔ Energy Efficiency & Sustainability

The strategic alliances of the company help customers minimize their energy use and reduce operational costs while achieving sustainability objectives.

Project solutions at KKR Bose Design receive market-leading expertise from the team who assures innovation and reliability throughout each solution creation process. We operate as a team which produces innovative heat exchange systems at reduced cost levels for our Singapore-based clientele.

Our Heat Exchanger Design Process:

Before starting a project at KKR Bose Design we evaluate thermal specifications and transfer rates and performance metrics to match the operational characteristics of Jurong Tuas Changi and other Singapore industrial zones.

Engineers at KKR Bose Design establish detailed initial designs by selecting materials appropriately along with optimizing flow quantities and heat production attributes for your precise usage case.

Through advanced simulation techniques that use modern tools we evaluate designs extensively to discover operational efficiencies which improve the performance quality. Simulation models enable our team to achieve project requirements while satisfying the industrial regulations of Singapore.

The production phase receives detailed manufacturing specifications and drawings from our team after completing their work. The data contains every requirement to expedite manufacturing and guarantee precise and affordable deployment across Singapore’s fast-paced industrial environment.

Our Heat Exchanger Design Expertise in Various Industries:

- Petrochemical

- Power Generation

- HVAC & Refrigeration

- Oil & Gas

- Food & Beverage

- Pharmaceutical

- Chemical Processing

Partner with Singapore’s Leading Heat Exchanger Design Experts

The expertise team at KKR Bose Design helps you achieve remarkable progress in solving intense thermal challenges. Our team provides trustworthy heat exchanger designs that precisely match your requirements where you operate at Jurong, Tuas, or Changi Business Park.

Contact our team today to benefit from Singapore’s most reputable design services for improved heat transfer system performance. Knowledgeable experts position us among the prime agencies in Singapore and other regions that provide heat exchanger design solutions. Our team exists to boost engineering performance levels.

Our heat exchanger design expertise caters to a diverse range of industries, including:

- Petrochemical

- Power Generation

- HVAC & Refrigeration

- Oil & Gas

- Food & Beverage

- Pharmaceutical

- Chemical Processing

Smart Heat Exchanger Design Starts with KKR Bose Design

Your thermal design problems require expert analysis at KKR Bose Design so our team can provide efficient solutions for every heat exchanger application and equation. Our team delivers results which meet performance requirements and cost-effectiveness for enhancing either established systems or new equipment development projects.

Contact our heat exchanger design experts at present time to achieve remarkable outcomes for your upcoming heat transfer needs. Our Indian heat exchanger design company leads the market as we provide industrial solutions to clients throughout Singapore’s industrial zones with expert engineering concepts and innovative solutions.

Advantages of KKR Bose Design Services:

Our pricing system combines cost-effectiveness with high-performance engineering to serve the industrial projects in Singapore’s competitive sector.

Our heat exchanger designs together with engineering solutions fulfill both international industry specifications as well as requirements of Singapore’s industrial marketplace.

Reliable thermal solutions emerge from our current usage of state-of-the-art simulation software in combination with design tools.

Our support team provides swift

response along with proactive behaviors to quickly resolve any service-related questions which maintains project progress.

We guarantee every project component arrives on time and executes without delay according to the set deadlines.

Professional solutions along with dedicated engineering support are offered to customers located at Jurong and Tuas and Changi Business Park and One-North through our team of qualified experts.

KKR Bose Design offers premium heat exchanger design services as a respected provider due to their engineering expertise which covers architectural and structural and mechanical competencies.

Heat Exchanger Services Offered by KKR Bose Design:

Our thermal and mechanical calculation services include all types of heat exchangers starting from shell and tube to plate and coil heat exchangers. Our service portfolio extends across multiple industrial fields along with different applications.

Types of Heat Exchangers Designed by KKR Bose Design:

- Shell and Tube Heat Exchangers

- Double Pipe Heat Exchangers

- Plate Heat Exchangers

- Air Coolers

- Condensers, Evaporators, and Boilers

- Other Custom Heat Exchanger Variants

We specialize in the thermal and mechanical design of these heat exchangers to ensure optimal performance in real-world applications. From basic shell and tube heat exchangers to more complex designs, we provide tailored solutions for every client.

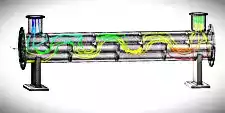

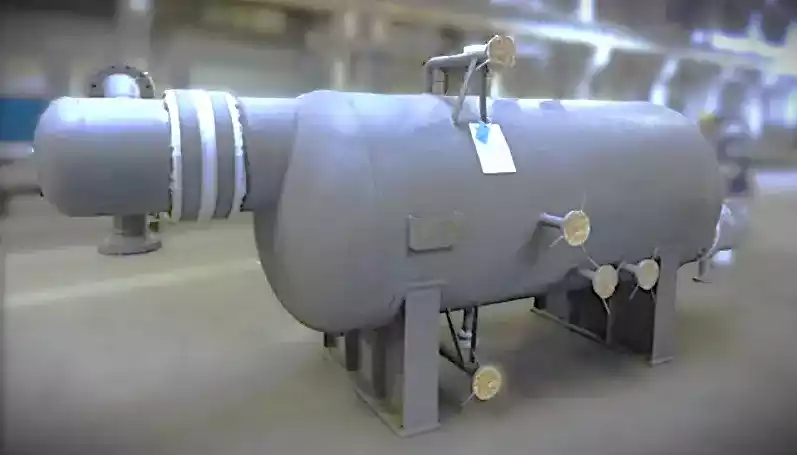

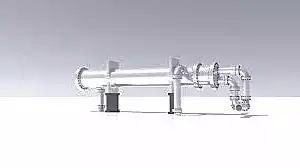

1. Shell and tube heat exchangers:

The simplest category of heat exchangers, STHXs are made up of one tube or multiple in parallel (known as a tube bundle of tubings encased inside a cylindrical chamber (the shell). These devices are designed in such a way that at least one is a flow of the first fluid through the small tube while the second fluid flows outside and over the inner surface of this tube as well as between the tubes in the enclosed chamber. Other design characteristics offered for this kind of heat exchanger are finned tubes, single or two phase transfer, counter current, co current or cross current flow patterns, single, two or multiple pass. The categories of shell and tube heat exchangers include helical coil heat exchangers and double pipe heat exchangers while some uses include preheating, oil cooling, and steam production. Shell and tube heat exchanger applications The following is a description of more uses of the shell and tube heat exchanger; A detailed view of a heat exchanger tube bundle. Heat exchanger tube bundle with a view at the microscale.

2. Double Pipe Heat Exchangers:

A class of shell and tube heat exchangers, double pipe heat exchangers are the simplest heat exchangers both in terms of design and layout and a utilize two or more concentric pipes or tubes, one being a larger outer tube and the other one or more inner tubes. This is in accordance with the design of all shell and tube heat exchangers in which one fluid circulates through the smaller tube(s), and the other fluid moves on the outside of the smaller tube(s) within the larger tube.

The design features that Double pipe heat exchangers share from the previous two types- recuperative and indirect contact are that the two fluids remain separated and flow through their own channel for the entire heat exchange process. Nevertheless, the double pipe heat exchangers are not very rigid when it comes to flow arrangements as they can be designed for cocurrent as well as countercurrent and can be used either in series, parallel or in series parallel arrangement in a system

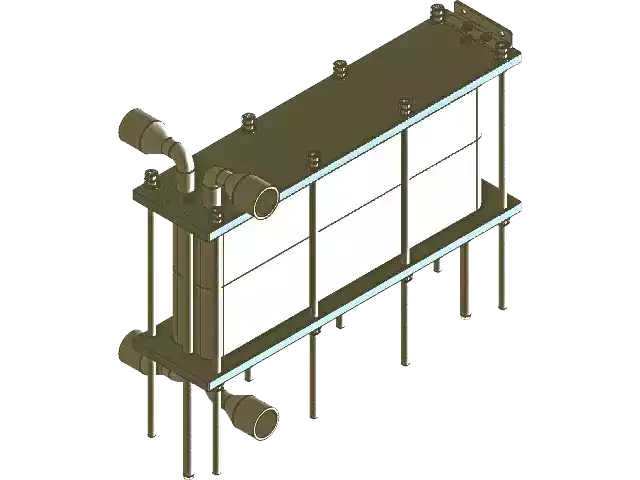

3. Plate Heat Exchangers:

It is also called as Plate type heat exchangers where several corrugated thin plates are grouped in a heap. Each pair of plates forms a passage where one of the fluids can pass while the pairs are bound and overlapped and connected, by bolting, brazing or welding in a way that they also form a second passage for the other fluid to pass through.

The standard plate is also available with modifications in the design such as in the plate fin or the pillow plate heat exchangers. The plate fin type of exchangers have raised or lowered fins or spacers on the plates and can have more than two arrangements of flow and more than two fluids passing through the exchanger. Pillow plate exchangers normally use pressure upon the plates in order to enhance the heat that needs to be transferred across the surface of the plates. Other types include; Plate and frame heat exchangers, Plate shell heat exchangers, and spiral plate heat exchangers.

4. Condensers, Evaporators, and Boilers:

Boilers, condensers and evaporators are heat exchangers which operate in two-phase heat transfer process. In single phase heat exchangers, one or both fluids may undergo phase changes while in the two-phase heat exchangers, heat transfer involve phase change such as conversion of the fluid from liquid to gas or vice versa.

Condensers are heat exchanging equipment’s that condense the hot gas or vapor by cooling it so as to convert it to liquid form. On the one hand, in evaporators, and boilers, the heat exchange transforming the fluids in the liquid phase to gas and vapour phase.

5. Other Heat Exchanger Variants:

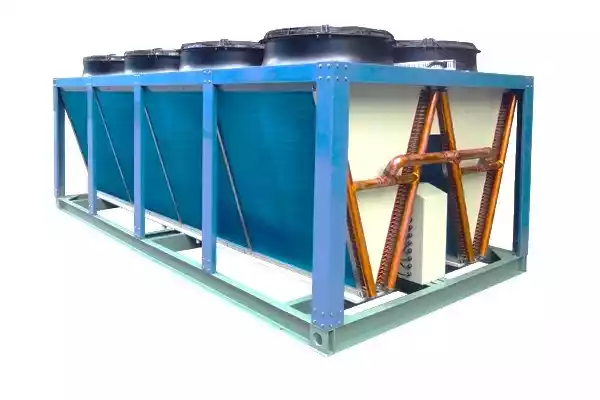

Heat exchangers are used in many different application types of the diverse branches of industries. Therefore it is possible to note that there are several types off heat exchangers available depending on the demand and the peculiarity of the certain program. Apart from the types of heat exchangers that have been described above, other other types of heat exchangers include air cooled heat exchangers, fan cooled heat exchangers and adiabatic wheel heat exchangers.

THERMAL & MECHANICAL Calculation for SHELL AND TUBE HEAT EXCHANGERS:

Shell and tube heat exchanger, Plate type heat exchangers, coil type heat exchangers, compact plates heat exchanger, double pipe heat exchanger, plate finned heat exchanger.

KKR Bose Design is one of the most successful design consultancy company for the past 12 years in the industries now our operations are spread over in India, United States ( US), Dubai, UAE, Middle East and United Kingdom ( UK). We also offer design calculations and detailing CAD drawings on petroleum Heat Exchanges which include Shell and tube and Plate type Heat Exchanges.

KKR Bose Design wide range of design services are including deferent type of heat exchangers

• FIXED TUBE SHEETS

• U TUBE

• FLOATING HEAD TUBE SHEET

• COAXIAL TUBES

• KETTLE TYPE RE-BOILER

• FINNED TUBES

• SHELL AND TUBE

• PLATE TYPE HEAT EXCHANGERS

KKR Bose Design Scope of Works are:

• Design under ASME SECTION VIII Div 1& Div 2, ASME sec 1, TEMA; API 660 & Detailed engineering

• Fabrication Drawings preparation.

KKR Bose Design Features:

- Flexible Solutions: We offer customized solutions designed to meet specific needs.

- High-Pressure & High-Temperature Capability: Our designs are suitable for challenging environments.

- Industry-standard Software: We use HTRI for thermal design and PV Elite for mechanical design.

- State-of-the-Art Tools: We use Aspen One Engineering and EDR for heat exchanger design and rating.

We offer timely and reliable services for:

As a service provider KKR Bose Design delivers complete thermal design and mechanical design alongside fabrication drawing solutions for heat exchangers to customers present in all major industrial areas of Jurong, Tuas, and Changi Business Park.

Our Expertise Includes:

KKR Bose Design handles Shell and Tube Heat Exchanger assessment of thermal performance through ratings as well as creating full detailed drawings for mechanical strength.

We assist clients through complete air-side and tube-side heat exchange process optimization via full thermal design and rating for Air Cooled Heat Exchangers.

Plate Heat Exchangers (PHE) need exact thermal design along with rating to guarantee the assembled product achieves necessary heat dissipating objectives.

Fired Heaters require thermal design and rating procedures to determine their operational feasibility within different environments for power-consuming heat transfer systems.

Plate-Fin Heat Exchangers receive thermal design and rating to achieve performance specifications based on complex thermal engineering criteria and industrial standards.

Customers can acquire Double-Pipe Heat Exchangers through precise design calculations alongside rating protocols for low-flow rate and compact heat transfer objectives.

We test and confirm the operational precision and functional capability of heat exchanger products that come from outside sources.

The tubular heat exchanger has become a standard due to its expansive surface area along with minimal shell-side pressure losses yet vibration problems tend to develop. Visual format analysis performed by our team provides both safety enhancements and performance improvements in designs.

Design-to-Fabrication Support

We function as an extension of fabrication firms since they use our organization to create design drawings. The company provides detailed thermal and mechanical designs for heat exchangers along with production-ready drawings that maintain their project timelines.

As a Singapore-based EPC consulting enterprise you can count on KKR Bose Design for outsource services regarding heat exchanger design work.

Heat Exchanger Network Design:

At KKR Bose Design, our heat exchanger design extends beyond individual equipment—to the entire network from the process perspective and the design viewpoint we achieve maximum thermal efficiency and system integration.

Our Heat Integration and Pinch Analysis services assists industries in Singapore to optimize their thermal systems by reducing number of exchanger, decreasing utility usage, and enhancing heat recovery. This results in greater energy efficiency, lower operations expenditure, and more sustainable operations.

We also help clients to validateexisting FEED (Front-End Engineering Design) or current thermal designs, delivering independent validation to check systems are fit for purpose and in compliance with international standards.

Our Heat Exchanger Engineered Services Are:

Thermal design of fixed tube sheet shell and tube heat exchangers (STHE)

Comprehensive thermal design of reboilers, condensers, and other heat recovery systems

Special heat exchanger thermal design solutions for both new and retrofit applications;

Knowledge in shell and tube heat exchanger design services, fully compatible to singapore’s industrial need and international codes

Although founded in Vadodara, India, KKR Bose Design is honored to count Singapore industrial estates to our clients, from Jurong Island and Tuas to Changi & One-North with international-wide state-of-the-art engineering expertise.

Heat Exchanger Network Design & Optimization:

At KKR Bose Design, we also specialize in heat exchanger network design and pinch analysis. This allows us to optimize the number of exchangers and reduce utility flows, leading to more efficient and cost-effective designs.

Heat Exchanger Products Designed by Referring to Codes/Standards:

- ASME Sec VIII Div I

- API-660

- TEMA

- GOST

- British Standards

- Indian Standards

- Australian Std. AS 1210

- Heat recovery heat exchangers design,

- Ambient air vaporizer design

- LNG vaporizer design

- Liquid Nitrogen, Liquid Oxygen vaporizer design

- Open rack vaporizer design

- Submerged Combustion Vaporizer design

- Shell & Tube Vaporizers

- Double pipe heat exchangers design

- Oil cooler heat exchangers design

- Air heated heat exchanger design

- Steam condenser heat exchanger design

- Air-Cooled Condenser for Steam Condensation Design HTRI

- Dynamic Modeling of Steam Condenser and Design

- Air conditioner condenser & evaporator design

- Intercooler & After Cooler heat exchanger design

- Feed water heater design & engineering

- Open and closed feed water heater design

- Thermal power plants feed water heaters design

- Boiler Feed water Heaters design

- LP / HP Boiler Feed water Heaters design

- Feed water Heater in Steam Power Plant design

- Feed water heater (LP/HP) – Shell and tube heat exchangers

- Feed water heaters for motor ships design

- Feed water Heater Tubes thermal design

- Air Conditioning – condenser & Evaporator design

- Oil cooled Shell and tube heat exchangers design

- Oil cooled all type of Heat Exchangers design

- Lube Oil Cooler Heat Exchanger design

- Oil/water cooled plate heat exchanger PHE design

- Hydraulic Oil Coolers (cooled) Shell and Tube Heat Exchanger design HTRI

- Oil Coolers for lubrication equipment design – Heat Exchangers –

- Turbine Lube Oil System all type of Heat Exchangers design. HTRI

- Engine Oil Coolers & all type of Heat Exchangers design

- Transformer-oil-cooler & all type of Heat Exchangers design

- Fan, Radiator, Coolant Recovery System, Heat Exchangers design HTRI

- Rice Mill Heat Exchangers design

- Pulp and paper industry heat exchangers design

- Oil & gas industry all heat exchangers design

- Refineries all heat exchangers design

- Petrochemicals all type of heat exchangers design.

- Thermal power plants all type of heat exchangers design

- Hydraulic power plants all type of heat exchangers design

- Nuclear power plants all type of heat exchangers design HTRI

- Fertilizer industries all type of heat exchangers design

- Dry wood pulp in pulp and paper mill steam coils design HTRI

- Welded plate Heat exchangers design for pulp and paper industry.

- Heat recovery heat exchanger design for pulp and paper industry.

- Plate heat exchangers,

- Spiral heat exchangers design HTRI

- Evaporation of sewage heat exchanger design

- Cooling of sewage heat exchanger design

- cooling of hydraulic oil heat exchanger design

- motors and gearboxes cooling heat exchanger design HTRI

- heating of steam process water heat exchanger design

- heat exchangers used in the offshore industry

- shell and tube exchangers;

- plate heat exchangers comprising a stack of thin plates;

- double pipe heat exchangers;

- and condensers, evaporators, and boilers.

- Heat exchanger design for preheating

- Air-Cooled Condenser for Steam Condensation Design HTRI

- Dynamic Modeling of Steam Condenser and Design

- Surface condenser design

- Hybrid steam condenser Design

- Steam Condenser Vacuum Calculations

- Steam Condenser: Basics, Parts, Advantages,

- Condensate Recovery System- Steam System

- Design of a steam plant condenser

- Standards for Steam Surface Condensers.

- Software thermal design – Multi Component Condensers

- Turbine Gland Steam Condenser HTRI

- Dump steam condenser

- Vertical-Fluted-Tube Condenser

- Large Steam System Condensers

- Flash steam condenser

- Condenser for steam turbine design HTRI

- Steam Surface Condenser Design

- Flash Steam Vent Condensers design HTRI

- Oil & gas, refineries oil heated heat exchangers design.

- Hot Oil System heat exchangers Design

- Storage tanks Steam Coil design

- Storage tanks Heating Coil Design

- Heating Coil Sizing For Fuel Oil Tank

- Sizing Heating and Cooling Coils for all equipment’s.

- Design of Coil Heat Exchanger

- Heating Coil in The Main Air Handling Unit design

- Crude Oil Storage Tank Heating Coil design

- heat exchanger design for heating and hot water production .

- Plate heat exchangers (PHEs) design

- Heat exchanger design for twisted geometries for biogas process

- U-pipe and Coaxial heat exchangers design.

- Shell and tube heat exchangers design

- Double pipe heat exchangers design

- Plate heat exchangers design HTRI

- Condensers, evaporators, and boilers.

- U-shaped finned heat pipe heat exchanger

- Copper Coaxial Heat Exchanger, Shell & Tube type design HTRI

- Thermal design and optimization of fin-and-tube heat exchanger

- Steam Operated Plate Heat Exchanger design

- Cross flow vs. counter flow heat exchanger design

- Falling Film Exchangers and Evaporators design

- Water Cooled Surface Condenser design

- ROTARY HEAT EXCHANGER design

- Horizontal and Vertical Condensers design

- Compact heat exchangers design

- Shell and tube heat exchanger

- Plate type heat exchangers

- Finned tube heat exchanger

- Compact plate heat exchanger

- Double pipe heat exchanger

- Plate fin heat exchanger

- Plate heat exchanger in oil refineries and oil production design

- Crude preheat train, heat exchanger design

- Crude heat exchanger , Primary distilled oil heat exchanger, Primary overhead oil heat exchanger,

- Overhead oil gas heat exchanger, Overhead oil-water cooler, First-line oil heat exchanger,

- Second-line oil heat exchanger, Third-line oil heat exchanger:

- Heat exchanger design for Heating of fuel-oil, diesel fuel, crude oil, kerosene, HVF, tar, etc.

- Heat exchanger design for Cooling of hydraulic turbine, transformer oil and lube oil

- Heat exchanger design for Heating of natural gas, before or after expansion HTRI

- (to avoid freezing the ground)

- Heat exchanger design for Heating of bitumen and coated materials

- Heat exchanger design for hating, and drying,

- Heat exchanger design for steam generation,

- Heat exchanger design for crude oil cooling

Our engineering services cover a wide variety of design and detailing services * Pressure Vessel Process design * Heat exchanger Thermal design * Heat exchanger design and detailing * Pressure vessel design and detailing * Separator and Deaerator design * Air cooled heat exchangers * Shell and tube heat exchangers * ‘U’ tube heat exchanger * Plate heat exchangers * Storage tanks * Oil coolers and other type of heat exchanger * Mechanical Calculations for all equipments * All type of mechanical parts detailing services Advantages of our Design Services: Some of the completed Heat exchanger works are: VOC Water Cooler for Allied Heat Transfer. * Use of the competitive price structure * Entailing Best quality performance services * Implementation of the most recent technology and techniques * Quick response to any of the service inquiries * Ensuring strict compliance with time table in all projects * Ensuring total customer satisfaction * Professionals and experienced personnel. Australia Exhaust Gas Cooler for Allied Heat Transfer Pulsation Bottle for Allied Heat Transfer Frying Oil Cooler for Allied Heat Transfer Power Station Bearing Oil Cooler for Allied Heat Transfer Spitfire – Air Cooler Heater for Allied Heat Transfer Overhead Condenser for Universal Heat Exchanger India Water Stripper Re–Boiler for Universal Heat Exchanger India U–TUBE Exchanger for Universal Heat Exchanger India Shell and Tube Exchanger for Universal Heat Exchanger India heat Hence with a good mix of experience and skilled CAD draftsmen, we are able to offer excellent quality of drawings that gives us a one-time client, a repeated customer.

Mumbai I Delhi I Kolkata I Chennai I Bangalore I Hyderabad I Ahmedabad I Pune I Seurat I Jaipur I Kanpur I Lucknow I Nagpur I Indore I Patna I Bhopal I Thane I Vadodara I Visakhapatnam

New York I Los Angeles I Chicago I Houston I Phoenix I Philadelphia I San Antonio I San Diego I Dallas I San Jose I Washington I Boston I Las Vegas I San Francisco I England I Birmingham I Glasgow I Liverpool I BristolENG I Manchester I Sheffield I Leeds I Edinburgh I Leicester I Northern Ireland I Scotland I Wales I London I Bradford

Bristol I Wakefield I Cardiff I Coventry I Nottingham I Sunderland I Belfast I Newcastle upon Tyne I Brighton I Hull I Plymouth I Stoke-onTrent I Wolverhampton I Derby I Swansea I Southampton I Salford I Aberdeen I Westminster I Portsmouth I York I Peterborough I Dundee I Lancaster

Oxford I Newport I Preston I St Albans I Norwich I Chester I Cambridge I Salisbury I Exeter I GloucesterLisburn I Chichester I Winchester I Londonderry I Carlisle I Worcester I Bath I Durham I Lincoln I Hereford I Armagh I Inverness I Stirling I Canterbury I Lichfield I Newry I Ripon

Bangor I Truro I Ely I Wells I St Davids I Antigua and Barbuda I Australia I The Bahamas I Barbados I Belize I Canada I Dominica I Grenada I Guyana I Ireland I Jamaica I Malta I New Zealand I St Kitts and Nevis I St Lucia

St Vincent and the Grenadines I Trinidad and Tobago I United Kingdom I United States of America I Toronto I Ontario I Quebec I Vancouver I British Columbia I Calgary I Alberta I Ottawa I St. John’s I Newfoundland I Charlottetown

Prince Edward Island I Saskatoon I Saskatchewan I Whitehorse I Yukon I Halifax I Nova Scotia I Banff I SYDNEY I MELBOURNE I BRISBANE I PERTH I ADELAIDE

Our Global Presence:

As one of the most successful design consultancy companies in the industry, KKR Bose Design has expanded its operations across India, United States, UAE, Middle East, and Singapore. We offer detailed design calculations and CAD drawings for petroleum heat exchangers, including shell and tube and plate type heat exchangers.

Wide Range of Heat Exchanger Design Services:

We offer design services for different types of heat exchangers, including:

- Fixed Tube Sheets

- U Tube Heat Exchangers

- Floating Head Tube Sheets

- Coaxial Tubes

- Kettle Type Re-boilers

- Finned Tubes

- Plate Type Heat Exchangers

KKR Bose Design Scope of Work:

We offer design services under various standards, including ASME Section VIII Div 1 & 2, TEMA, API-660, and detailed engineering. Our work includes creating fabrication drawings and ensuring compliance with industry standards.

Contact KKR Bose Design:

For more information or to start your heat exchanger design project, contact KKR Bose Design today. Whether you need thermal calculations, mechanical design, or fabrication drawings, we are your trusted partner in Singapore and around the world.